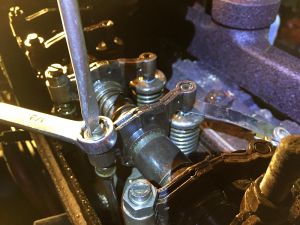

I started thinking about this question when a local farmer brought me a 1953 Super C Farmall tractor that I had rebuilt the engine for twenty years ago. This tractor was his granddad’s and no longer served the farm, except to be driven in parades. My job was to perform a tune-up for the upcoming spring parade and show season.

Which was first?

It is often debated who built the first internal combustion engine, whether it was the French engineer J.J. Etienne Lenoir in 1859, American engineer George Brayton in 1873, or Nickolaus Otto who patented the first four-stroke engine in Germany in 1885. However, it is common knowledge that in 1885, Gottlieb Daimler invented a prototype that resembled today’s modern gasoline engine.

Is it different?

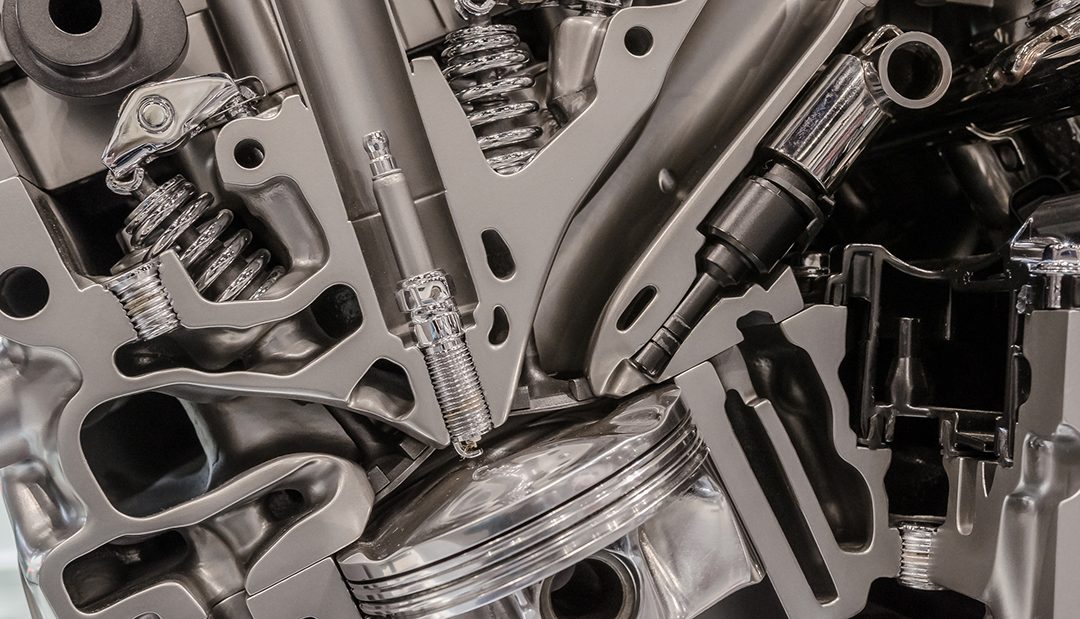

This is a bold statement, but the basic engine has not changed since Otto or Daimler first designed it. It requires fuel, oxygen, heat (ignition source), and a mechanical assembly to harness and control the resulting explosion. The delivery and control of these items have changed drastically over the past 130 plus years, but the original theory still holds true. The components of today’s engine are drastically different than even 50 years ago, but the result is the same fuel and air in, power out. The harnessing of that power from a fuel source is very similar across the wide variety of internal combustion engines, even today.

The basic engine has not changed, but the appearance certainly has. Daimler would be confused and amazed at the engine under the hood of today’s modern vehicles. I have met some great mechanics that were at the top of the trade in their prime, and they would hold that same amazement at what is happening under the hood of the 2018 vehicle.

The job at hand

It is a pretty straight-forward job to take a very basic designed internal combustion engine and improve its performance. Having grown up in a farming community, I started my career in the repair industry adjusting valves and points both in tractors and grain trucks. Then I transitioned into electronic ignitions, non-adjustable valve trains and now coil on plug and variable valve timing.

As I adjusted the valves on the old Farmall, I wondered if a student in a high school program would wonder why this needed to be done. While cleaning and adjusting the points, I wondered if a new, straight out of a community college program technician ever needs to adjust a set of points. Is it possible that young technicians only understand ignition from the use of a crankshaft sensor? I then questioned if the new automotive technician needs to know how to adjust a set of points or adjust the gap on an intake or exhaust valve. Personally, I am not sure they need to know these specific tasks. They may simply need to understand the basics of the internal combustion engine.

As I adjusted the valves on the old Farmall, I wondered if a student in a high school program would wonder why this needed to be done. While cleaning and adjusting the points, I wondered if a new, straight out of a community college program technician ever needs to adjust a set of points. Is it possible that young technicians only understand ignition from the use of a crankshaft sensor? I then questioned if the new automotive technician needs to know how to adjust a set of points or adjust the gap on an intake or exhaust valve. Personally, I am not sure they need to know these specific tasks. They may simply need to understand the basics of the internal combustion engine.

As technicians, we need to understand the basics of the four-stroke engine, and I have been amazed over the years. When training college students on the high-pressure pump in a direct injected engine that is running off the camshaft, some of the students aren’t sure about something as simple as camshaft rotation in relation to crankshaft rotation. Some of them do not know that it is a two to one ratio on the standard timing chain setup. I strongly feel that these basics are imperative to know in order to be a respected technician in the bay. But, to know how to adjust valves or diagnose an EECIII Ford system or power flow through a turbo 400 tranny, these items are not imperative for tomorrow’s technician. What is important is to know the hows and whys of today’s systems, such as CAN bus, variable valve timing, emission controls, and direct injection, just to name a few.

What is the true value?

As I went through the steps of the tune-up on this 1953 engine, manufactured by International Harvester, I wondered what made me qualified to do this job of adjusting a set of points or the valves and then tomorrow diagnose a no start caused by a faulty crankshaft position sensor. I believe it is training and experience, neither of which just happen. Training must be pursued; it doesn’t come to you. Experience, on the other hand, will gradually come to you. Both are required for the technician to become proficient at their duties and survive within the industry of repair.

“The only source of knowledge is experience.”

Albert Einstein

This is one of the reasons why I am excited about the Technician.Academy Respect is Learned© campaign. It may just be a play on words, but for tomorrow’s technician to achieve the respect the position deserves, experience and training will have to be earned by learning. Learning through training and experience will bring the respect that today’s and tomorrow’s top technicians deserve.

“Training is no longer a fixed event, but a lifelong journey along the career path.”

From Thomas Friedman’s book “Thank You for Being Late”

Are you Thankful?

I am thankful to have experienced the many changes to the automotive engine and the way it has been controlled over the past thirty years. I am also thankful that I have been able to gain plenty of training and experience in vehicle repair. I am curious to see how the internal engine will change in the next five, ten, or even thirty years. I truly believe the next ten years will bring changes to this industry unlike any we have seen up till now. The one thing that I believe will still hold true ten or even thirty years from now is Respect will be Learned by both training and experience in the bay.

“Anyone who stops learning is old, whether at twenty or eighty. Anyone who keeps learning stays young. The greatest thing in life is to keep your mind young.”

Henry Ford

As always, I encourage your comments and opinions on this and any other automotive topics. Email me at [email protected] or call 812-618-6101.