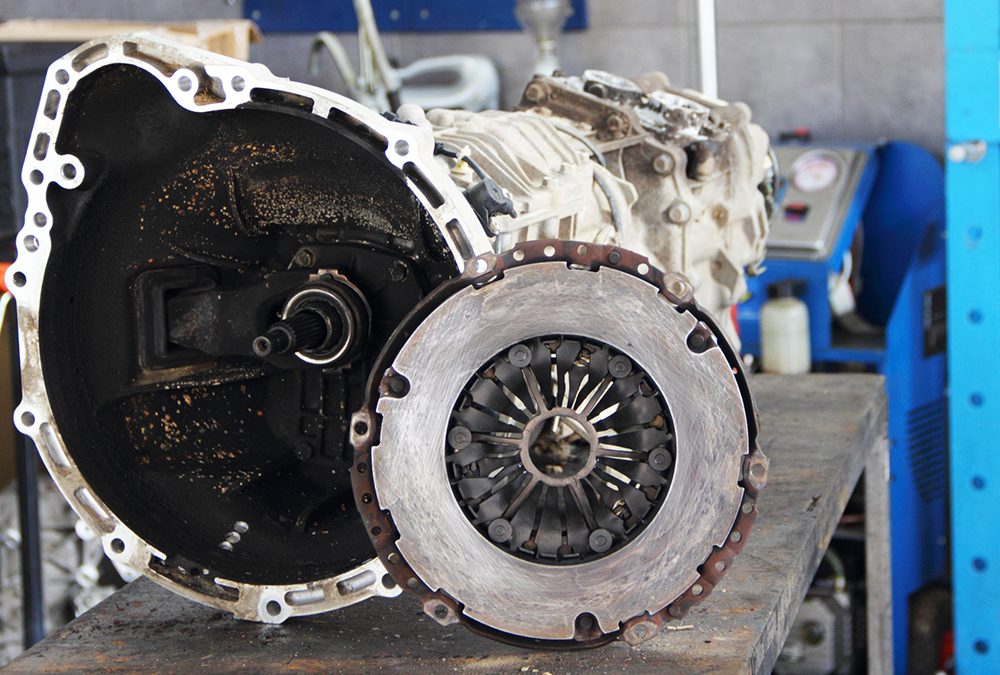

A friction clutch plate is used in vehicles to allow the transmission input shaft and engine to run at the same speed when rotating. The friction that is created between the engine and the transmission is what provides the force required to move the vehicle. When the clutch is engaged, the friction plate is sandwiched between the engine flywheel and a steel pressure plate that is bolted to the flywheel. If the pressure between the flywheel and pressure plate is not sufficient, it will allow the friction plate to slip and thus the vehicle will not perform correctly.

How the Clutch Plate Works

There are six major parts when it comes to how a friction clutch will work. The first is when the driver pushes in the clutch pedal of the car. This will release a fork that begins to push onto the throw-out bearing that in turns presses on a spring. This diaphragm spring will then engage and disengage the clutch to force it away from the flywheel. Once the clutch is not held against the flywheel, the clutch will disengage. Since there can be so much wear and tear on the clutch plate and flywheel, a lot of machines will use wet clutches. These clutches are lubricated to help them run smoothly and to slow down the wearing out that is caused by the constant friction, while a dry clutch will wear out faster due to the lack of lubrication.

Serve Your Clients with Quality Products from a Reputable Company

As a business owner, you know that you want to provide your customers with quality products and great service. Why would you settle for less when it comes to purchasing automobile parts? From clutch plates to torque converter wafers, search for a trustworthy company that will not only provide you with quality products but also at an affordable price. You do not want to provide your clients with parts that may not last long or work effectively. This is why you should find a business you can depend on to provide products that will last a long time, and you are able to pass the savings onto your customers.