If you own a vehicle and like to be aware of possible repair needs, you may be curious as to what a clutch pressure plate is.

The Clutch Pressure Plate Controls Engine Torque

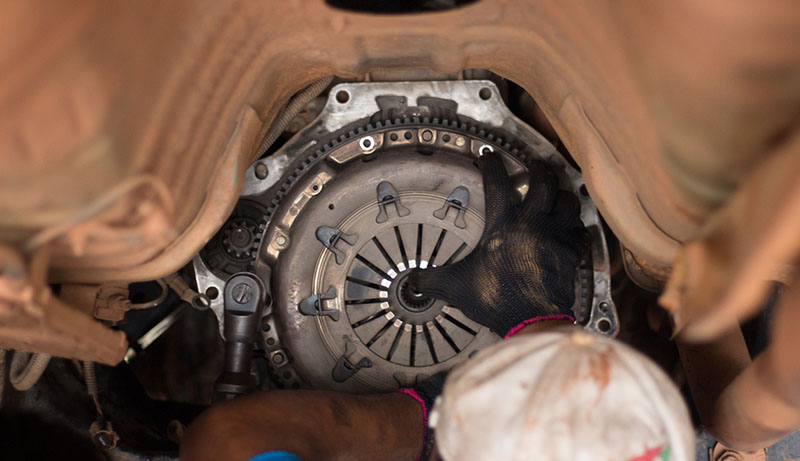

A car’s clutch pressure plate is the mechanism that transfers the engine torque to the transmission input shaft through the clutch disc. Thereby, it is a vital part in the functioning of a manual transmission. A clutch pressure plate lives up to its name in the fact that it is round-shaped. Plus, it is a metal component that has springs and levers inside of it that are controlled by a release fork attached to a shifter.

As the car’s driver steps onto the clutch pedal, the springs inside the pressure plate are compressed, pull the plate away from the clutch flywheel, and stop the clutch disc from moving. Then, the driver shifts into the desired gear and releases the pedal and the levers release and the springs expand and push the clutch plate back into the disc, which engages the flywheel and gets your vehicle wheels powered again.

Three Kinds of Pressure Plates

There are three main kinds of clutch pressure plates: a long style with nine springs and three levers, which is used mostly for racing; a Borg and Beck style with nine springs and three levers (which are wider than the first type levers) that is for street driving and is a more durable and robust part; and finally, the diaphragm pressure plate, which is also used for street driving and is a common kind usually seen in late model vehicles. The diaphragm pressure plate has one Bellville style of spring that puts an even load onto the pressure plate to the flywheel. Plus, it requires less effort from a driver to put the car into gear.